Composite Fatigue

複合材進展性損傷/破壊評価解析ソフトGENOA/MCQ -機能情報

GENOA-Composite Fatigue

In materials science, fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. Fatigue occurs when a material is subjected to repeated loading and unloading. If the loads are above a certain threshold, micro-cracks will begin to form and grow. Ply is weakened due to matrix cracking and will failure under fatigue loading due to delamination and fiber failure. The shape of the structure will significantly affect the fatigue life; square holes or sharp corners will lead to elevated local stresses where fatigue cracks can initiate. Round holes and smooth transitions or fillets are therefore important to increase the fatigue strength of the structure. Several types of fatigue loading must be accounted for, some are listed here: low cycle fatigue, high cycle fatigue and random fatigue using spectrum loading. High cycle fatigue usually deals with situations that require more than 10,000 cycles to failure. In some applications, fatigue loading includes changes in stress ratio, frequency, or temperature between several stages of the loading process. This is referred to as multi-stage fatigue.

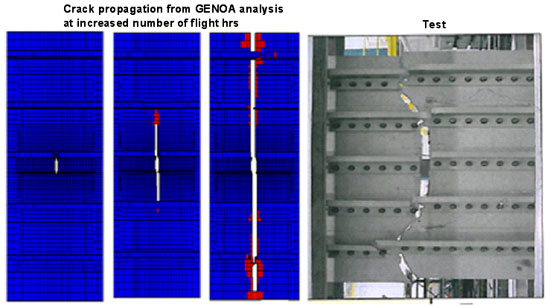

Validation of Fatigue Crack Growth of Aircraft Panel Under Tension Fatigue Loading; Panel is made from CentrAl Fiber Metal Laminate [4]

Challenge

Main challenges with composite fatigue are the determination of:

- Constituents fatigue properties (strength cycle S-N curve)

- Effect of defects and environment on fatigue properties of the lamina

- da/dN curve for crack growth under fatigue loading. Other challenges are associated with the accumulation of damage under multi-stage fatigue loading and with dealing with the probabilistic nature of composite.

Implications

Relying on test alone to qualify material or structure under fatigue loading is cost prohibitive. Limited tests can be used to guide the fatigue life assessment of composite strictures at various levels of the building block (coupon, element, sub-component, and component). Not accounting for the probabilistic nature of composite and manufacturing defects, can result in reduced durability and reliability, and in increased risk to the structure.

How we address it

By use of multi-scale based progressive failure analysis integrated with finite element solution. Traditional finite element analysis (FEA) solvers assess damage at the lamina level whereby damage initiates at lower scale in the fiber and matrix.

GENOA Progressive Failure Analysis augments finite element analysis with multi-scale composite mechanics, and damage tracking and fracture to determine damage evolution under single or multi-stage fatigue loading condition. It identifies the number of cycles where damage or delamination initiates and grow to failure. It also identifies location and types of damage/failure modes. Damage is accumulated for each fatigue cycle loading. Damage history and damage indices are extracted for use in subsequent analysis. For fatigue crack growth, AlphaSTAR developed an approach that enable the generation of da/dN curve starting from fracture toughness properties. It also established a process for reverse engineering of fatigue constituent properties starting from lamina fatigue properties. Technology is applicable to polymer composites, hybrid material (fiber metal laminate), and sandwich materials and structures.

Benefits Provided

- Reverse engineering of constituent fiber and matrix fatigue properties

- Calculation of da/dN curve using mode I and II fracture toughness properties

- Capture damage and fracture evolution process under all types of fatigue loading

- Determine how failure occurs and how to fix it.

- Reduce number of tests by relying on accurate analysis and simulation methods.

- Can be used to guide testing of critical structures under fatigue loading (example, what is the maximum number of cycles to test without compromising the structure itself?)

- Eliminate unnecessary increase in weight by inclusion of effects of scatter in properties and manufacturing

- Increased durability and reliability

Testimonials

AlphaSTAR designed critical aerospace and automotive structures for low/high/random/multi-stage fatigue applications including civilian and military applications. Some references from open literature are listed below:

- References

- [4] M. Garg, F. Abdi, and G. Abumeri, and M. Heinimann, “Fatigue Life Prediction of Center Cracked CentrAl Stiffened Panel Subject to Spectrum Loading”, AIAA-SDM 2011 conference, Denver Colorado.