機能

複合材進展性損傷解析ソフトGENOA -機能

材料評価解析ソフトMCQ -機能

特徴・アプリケーション

特徴

製品設計レベルの3次元構造体モデルを用いた解析が可能

GUIによる容易なモデル、解析設定制御

各汎用FEソルバー、モデルを使用

複数荷重、荷重スペクトラムなどの制御も可能

アプリケーション例

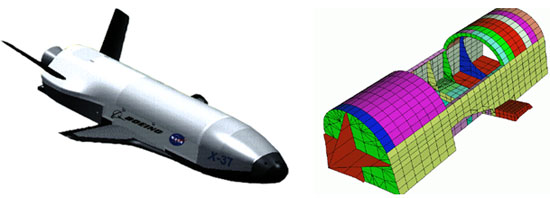

航空宇宙: 複合材の疲労寿命予測、き裂進展予測, 材料の特性評価:

許容強度,製造時のスプリングバック、硬化、欠陥の影響,エンジン-セラミックスメーカー

自動車:複合材の圧壊&衝突、衝撃解析など

短繊維、COPV-水素タンクのフィラメント・ワインディング成形など

エレクトロニクス:熱-構造変形(ボールグリッドアレイ)

インフラ:複合材橋、パイプ、海上石油掘削プラットフォーム

タービンブレード

スポーツ用品

Impact -GENOA

Soft Body Impact SimulationCopyright J. Bayandor, CRASH Lab, Virginia Tech

Composite automotive and aerospace structures are subjected to various types of impact loading in service. The impact loading can be characterized into two categories: low and high velocity. The ability to accurately design for impact is key to the reliability and safe operation of the product or structure. AlphaSTAR developed and validated analytical simulation methods for assessing impact resistance characteristics of composite structures. The capability is suitable for modeling: automotive crush and crash events; impact and post-impact residual strength assessment under tension, compression, or shear; hail impact on aerospace structures, and for bird strike analysis and certification.

Challenge

Assessing composite or sandwich structures damage under impact loading is challenging as it requires integration of explicit dynamic finite element solution with damage tracking and fracture. The loading is usually in perpendicular direction to the main axis of structure exhibiting different failure mechanisms as compared to those experienced under static loading. Other challenges stem from determination of strain rate effect on material properties. Traditional methods are capable of assessing peak load but lack when it comes to simulating the failure process observed in test.

Most analytical models are adjusted to replicate test behavior, especially for high velocity impact. (i.e. bird strike simulation). The challenge is to provide a priori prediction of test behavior rather than just duplicate test behavior, especially in high strain and deformation fields. The focus of AlphaSTAR is to provide engineers with a reliable tool for assessing behavior of structures under all types of impact loading.

Implications

Relying on test alone to design for impact loading compromises the durability, reliability, integrity, and operational safety of the structure. This lead to an increase in weight to account for scatter in impact conditions under service.

How we address it

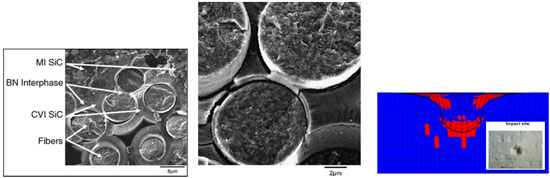

By use of multi-scale based progressive failure analysis integrated with explicit dynamic finite element solution. Most explicit finite element analysis (FEA) solvers assess damage at the lamina level whereby damage initiates at lower scale in the fiber, matrix, and interphase.

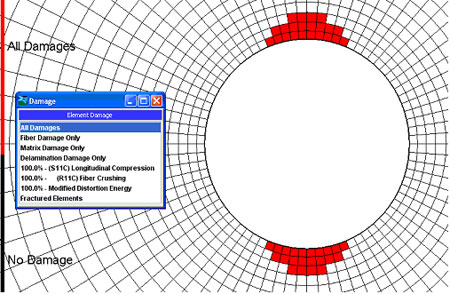

GENOA Progressive Failure Dynamic Analysis PFDA augments Explicit Dynamics (ED) finite element analysis with multi-scale composite mechanics, and damage tracking and fracture to determine all stages of damage evolution under impact, crush, or crash loading condition. The methodology determines conditions for damage/delamination initiation and growth to fracture. The damage tracking is done by identifying and accumulating damage at the “root cause” of the composite in matrix and fiber using dedicated physics based damage and failure criteria. PFDA calculates crack density, micro-cracks in the matrix, delamination within the plies, and fiber failure in tension and compression including micro-buckling.

Benefits Provided

- Capture damage and fracture evolution process under impact loading.

- Determine how failure occurs and how to fix it.

- Reduce number of tests by relying on accurate analysis and simulation methods.

- Eliminate unnecessary increase in weight by determining the residual strength post impact.

- Increased durability and reliability.

- Inclusion of material properties due to high strain rate effect.

Composite Fatigue -GENOA

In materials science, fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. Fatigue occurs when a material is subjected to repeated loading and unloading. If the loads are above a certain threshold, micro-cracks will begin to form and grow. Ply is weakened due to matrix cracking and will failure under fatigue loading due to delamination and fiber failure. The shape of the structure will significantly affect the fatigue life; square holes or sharp corners will lead to elevated local stresses where fatigue cracks can initiate. Round holes and smooth transitions or fillets are therefore important to increase the fatigue strength of the structure. Several types of fatigue loading must be accounted for, some are listed here: low cycle fatigue, high cycle fatigue and random fatigue using spectrum loading. High cycle fatigue usually deals with situations that require more than 10,000 cycles to failure. In some applications, fatigue loading includes changes in stress ratio, frequency, or temperature between several stages of the loading process. This is referred to as multi-stage fatigue.

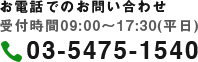

Validation of Fatigue Crack Growth of Aircraft Panel Under Tension Fatigue Loading; Panel is made from CentrAl Fiber Metal Laminate [4]

Challenge

Main challenges with composite fatigue are the determination of:

- Constituents fatigue properties (strength cycle S-N curve)

- Effect of defects and environment on fatigue properties of the lamina

- da/dN curve for crack growth under fatigue loading. Other challenges are associated with the accumulation of damage under multi-stage fatigue loading and with dealing with the probabilistic nature of composite.

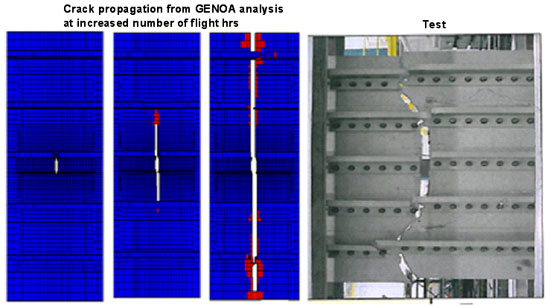

Implications

Relying on test alone to qualify material or structure under fatigue loading is cost prohibitive. Limited tests can be used to guide the fatigue life assessment of composite strictures at various levels of the building block (coupon, element, sub-component, and component). Not accounting for the probabilistic nature of composite and manufacturing defects, can result in reduced durability and reliability, and in increased risk to the structure.

How we address it

By use of multi-scale based progressive failure analysis integrated with finite element solution. Traditional finite element analysis (FEA) solvers assess damage at the lamina level whereby damage initiates at lower scale in the fiber and matrix.

GENOA Progressive Failure Analysis augments finite element analysis with multi-scale composite mechanics, and damage tracking and fracture to determine damage evolution under single or multi-stage fatigue loading condition. It identifies the number of cycles where damage or delamination initiates and grow to failure. It also identifies location and types of damage/failure modes. Damage is accumulated for each fatigue cycle loading. Damage history and damage indices are extracted for use in subsequent analysis. For fatigue crack growth, AlphaSTAR developed an approach that enable the generation of da/dN curve starting from fracture toughness properties. It also established a process for reverse engineering of fatigue constituent properties starting from lamina fatigue properties. Technology is applicable to polymer composites, hybrid material (fiber metal laminate), and sandwich materials and structures.

Benefits Provided

- Reverse engineering of constituent fiber and matrix fatigue properties

- Calculation of da/dN curve using mode I and II fracture toughness properties

- Capture damage and fracture evolution process under all types of fatigue loading

- Determine how failure occurs and how to fix it.

- Reduce number of tests by relying on accurate analysis and simulation methods.

- Can be used to guide testing of critical structures under fatigue loading (example, what is the maximum number of cycles to test without compromising the structure itself?)

- Eliminate unnecessary increase in weight by inclusion of effects of scatter in properties and manufacturing

- Increased durability and reliability

Testimonials

AlphaSTAR designed critical aerospace and automotive structures for low/high/random/multi-stage fatigue applications including civilian and military applications. Some references from open literature are listed below:

- References

- [4] M. Garg, F. Abdi, and G. Abumeri, and M. Heinimann, “Fatigue Life Prediction of Center Cracked CentrAl Stiffened Panel Subject to Spectrum Loading”, AIAA-SDM 2011 conference, Denver Colorado.

Residual Strength Determination -GENOA

Residual strength is the load or cycles (usually mechanical) that a damaged structure or material can still carry without failing. This type of analysis requires an understanding of damage state in a given structure. The damage can be caused by in-service loading, such as introduction of micro-cracks in a composite panel, or damage and delamination in a panel when subjected to impact loading. The capability is critical for aerospace and infrastructure applications where post damage response is of great importance. For example, when fatigue causes a crack in an aircraft panel to grow in flight, residual strength analysis is crucial to determine how many more cycles can the aircraft sustain for safe landing assessment. Another example, what is the reduction in compressive strength of a stiffened panel after the panel is subjected to low velocity impact. Integrated computational simulation such as the one developed by AlphaSTAR, can be used to determine post damage reduction ins residual strength.

Objective

Provide analysts and designers with accurate computational simulation capability to determine residual strength following a specific damage event (example: tension after impact TAI, compression after impact CAI and shear after impact SAI, residual strength after discrete source damage in a stiffened panel of wing).

Approach

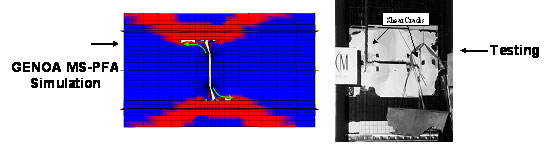

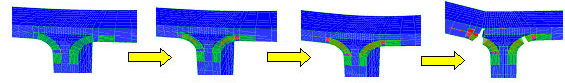

Use GENOA’s multi-scale progressive failure analysis MS-PFA to determine all stages of damage evolution under service loading. Damage evolution comprises damage initiation and propagation (including delamination). MS-PFA is finite element based progressive failure analysis that augments traditional commercial FEA stress solvers for durability and damage tolerance. It allows the extraction of damage history for use in post-damage residual strength calculation.

Tools Used

Relevant GENOA modules are MS-PFA: static, fatigue, and impact (explicit). For example, low or high cycle fatigue analysis for a given number of cycles, then damage history is extracted from fatigue analysis for use in determining maxim static failure load (as typically done for aircraft panels or wing component).

Benefits Provided

- Determine damage history under service loading.

- Determine post damage residual strength including failure modes and failure location)

- Answer what can be done to improve residual strength post damage

- Evaluate and manage risk associated with certain damage events

Past Experience

Technology was applied successfully to determine post impact residual strength on coupon and element, and component level structures made polymer composites. Furthermore, it was applied to determine residual strength on wing structures after fatigue.

Durability and Damage Tolerance -GENOA

Durability and damage tolerance (D&DT) of composite structures is a very important element of the overall design process. For airframe structures, durability and damage tolerance provide guideline for setting up an inspection plan for each principal structural element so damage (including micro-cracks) under service loading do not grow to failure prior to detection. It is imperative to assess all stages of damage evolution in composite structures to determine when, where, and why damage and fracture initiate and propagates. AlphaSTAR integrated D&DT methods with damage tracking and fracture and finite element analysis to evaluate damage growth in composite structures. It allows the analyst to include in the D&DT analysis manufacturing defects depicting “as-is” state of the structure.

Objective

Provide stress engineers with robust methodology for determining all stages of damage evolution in composite structures and answer critical design questions on why, where, and when damage and fracture initiates and what can be done to fix it.

Approach

Use GENOA’s multi-scale progressive failure analysis MS-PFA to determine all stages of damage evolution under service loading. Physics based composite damage and failure mechanisms are used by MS-PFA to interrogate the structural response. Matrix cracking under tension, compression, shear, and fiber failure under tension and compression (including crushing, fiber-matrix debonding, and fiber micro-buckling) are evaluated. Analyst has a choice of using fiber/matrix or ply properties as input to the analysis. Commercial FEA stress solvers such as (NASTRAN, ABAQUS, ANSYS, and others) are augmented for damage tracking and fracture with GENOA’s MS-PFA.

D&DT is evaluated under all types of loading including static, dynamic (low/high velocity impact), low/high cycle fatigue, and creep loading.

Tools Used

Relevant GENOA modules are MS-PFA: static, fatigue (low cycle/harmonic/ random/power spectrum density, single and multi-stage), and impact (explicit low and high velocity).

Benefits Provided

- Determine damage history/locations/modes under service loading.

- Determine ultimate (failure) load

- Evaluate and manage risk associated resulting from scatter and manufacturing defects (effect of void variability on compression strength, shape of void, location of void, etc.)

- Test guidance by obtaining a priori prediction to determine where to place instrumentation

- Identify test anomalies

- Aid in re-design of structural component

- Develop an inspection plan

- Support certification plans

- Supports test reduction goals

Past Experience

D&DT of composite aircraft and automotive structures and bridges. Examples include low and high velocity impact of aerospace and automotive structures, progressive failure analysis of stiffened wing and fuselage panels, and wing structures. Technology was validated for every step of the FAA building block approach (from coupon level to sub-element, element, and structural components),

D&DT Approach is Applicable to all Levels of FAA Building Block

D&DT of A Stiffened Wing Panel With Discrete Source Damage Under Tension

Ref: F. Rognin, H. Zhang and F. Abdi, K. Nikbin, “Robust Design of Composite Stiffened Panels under Discrete Source Damage, a Combined Durability-Reliability Evaluation”, 51th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Orlando, Florida, 12-15 April 2010.

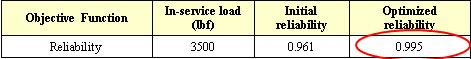

Robust Design -GENOA

Robust design is a process that ensures that a given design is characterized with maximum reliability, maximum durability, and minimum weight. The approach ensures that the performance of the considered structural component is insensitive to small scatter or variations in material properties, manufacturing, loads, and geometry. With the use of composites, robust design is used to prevent initial micro-racking and initial delamination from growing to pose a threat to the integrity of the structure.

Damage Evolution as Load Increases – Naval Joint Load Displacement (Analysis and Test)

Objective

Provide design engineers with robust methodology for sizing structural components to meet requirements for reliability, durability, and weight.

Approach

Use GENOA’s multi-scale progressive failure analysis MS-PFA robust design module considering uncertainties in material properties, manufacturing, geometry, shape, and loads. Manufacturing variables include composite layup and ply thickness. The capability delivers optimized manufacturing variables for maximum reliability, maximum durability, and minimum reliability. Sensitivity analysis is used to identify critical design variables that influence the reliability, durability, and weight.

Robust design is done using any in-service loading including static and fatigue.

Tools Used

Relevant GENOA modules are MS-PFA Robust Design and Probabilistic Analysis Modules.

Benefits Provided

- Quantification of reliability for a given design

- Provide alternate designs for weight management

- Identify and control influential sources of scatter to minimize variability in the design

- Support test reduction goals

- Shorten iterative design cycles

- Reduce risk by maximizing reliability and durability

- Robust design of aircraft panels and automotive suspension systems.

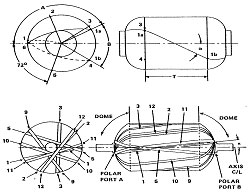

Filament Winding -GENOA

A composite overwrapped pressure vessel (COPV) is a vessel consisting of a thin, non-structural liner wrapped with a structural fiber composite, designed to hold a fluid under pressure. The liner provides a barrier between the fluid and the composite, preventing leaks, which can occur through matrix micro-cracks. The most commonly used composites are fiber reinforced polymers (FRP) using carbon and kevlar fibers. AlphaSTAR is experienced in modeling, analysis, and design of composite pressure vessels for both automotive and space applications.

Classes of COPVs modeled with GENOA-FW module

Challenge

Effective design of composite tanks is challenged by the ability of accurately determining onset of specific events such as: crack formation, leakage, slippage of gas between dome and valve assembly, and rupture of tank. Other challenges pertain to accurate determination of: ply angle distribution; residual stresses due to winding and curing; tank reliability due to scatter in manufacturing parameters, defects, and material properties; strength allowables for risk reduction; tank autofrettage; addressing variability in tank performance considering “As-designed” versus “As-built” and “As-is”; and tank certification. Some composite tank structures undergo numerous temperature / pressurization cycles causing an onset of delaminations and micro-cracking. Delaminations occur because of the differential movement of the layers caused by CTE mismatches between the layers. After successive cool-and-heat cycles, the weak adhesive bond between the layers degrades and breaks.

Typical filament winding details used as input

Implications

Tank leakage tends to occur when micro-damages in the tank wall materials exceed tolerable levels, which may cause catastrophic tank failure. Production cost and weight of tanks are increased to improve durability and reliability of these structures.

How we address it

It is addressed by use of multi-scale based progressive failure analysis with robust design. Most finite element analysis (FEA) solvers assess damage at the lamina level whereby damage initiates at lower scale in the fiber, matrix, and interphase. These challenges are addressed by AlphaSTAR through an integrated capability that couples winding analysis with multi-scale progressive failure analysis including modeling of defects and uncertainty analysis. GENOA Filament Winding, progressive Failure Analysis and robust design modules are used to model, analyze, and design COPVs with minimum weight and with improved durability and reliability.

Benefits Provided

- Reduce number of design and certification tests by relying on accurate analysis and simulation methods.

- Reduced weight.

- Increased durability and reliability.

- Enable large scale production of tanks by eliminating/controlling sources that produce anomalies.

- Testimonials

- [1] Christopher P. Keddy, “Composite Overwrapped Pressure Vessel Modeling and Analysis”, White Sands Test Facility, Johnson Space Center, July 2008.

Material Characterization -MCQ

Material Characterization of Tape, and 2-D/3-D Braided/Woven Compositesf

An important part of certification planning is to conduct complete material characterization to assess composite laminate response considering “as-built” and/or “as-is” material states: manufacturing anomalies (i.e., void size/shape, fiber waviness, interphase coating), design (i.e., ply orientation, thickness, 2D/3D architecture). Composite are being used in aerospace, automotive, wind turbine, ship building, and infrastructure industries. It is important to identify root cause for composite damage and failure thru comprehensive material characterization that involve;

- Reverse engineering of constituent fiber and matrix properties;

- Determination of material design envelope;

- Determination of material response under in-service environments including temperature and moisture loading;

- Generation of carpet plot to provide alternate laminates for design consideration;

- Generation of A- and B-Basis strength allowables;

- Accelerate material selection for use in certification;

Objective

Provide material and structural engineers with verified capability for rapid and accurate assessment of laminate response under in-service loading.

Approach

Use GENOA’s MCQ module integrating micro and macro-mechanics with damage tracking by assessing physics based damage and failure criteria encountered in composites. Material response is interrogated to determine loads that produce matrix cracking under tension, compression, shear, and fiber failure under tension and compression (including crushing, fiber-matrix debonding, and fiber micro-buckling) are evaluated. Analyst has a choice of using fiber/matrix or ply properties as input to the analysis. MCQ does not use finite element theory, rather it uses nit cell approach depicting ASTM specimen with uniform state of stress.

Tools Used

GENOA’s MCQ module are used for:

- Fiber, Matrix, and Lamina Calibration – Reverse engineer effective linear fiber/matrix properties from lamina or laminate test data (strength and stiffness). The effective properties accounts for the thermal residual stresses and interface due to curing process.

- Non-Linear Material Characterization Optimization (MCO) – Reverse engineers effective fiber, matrix, ply non-linear properties (stress strain curves) from ply or from laminate test data.

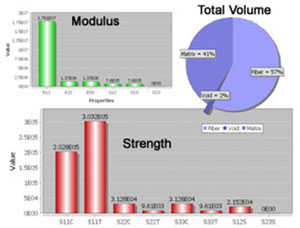

- Ply Level Analysis – Predicts equivalent ply properties (mechanical/thermal/electrical) using fiber matrix properties as input. Example of mechanical properties (Figure 1) is ply strength in 11, 22, 33, 12, 23, and 13 directions. Example of electrical properties is ply and laminate conductivity.

- Laminate Analysis – Predict equivalent laminate properties using fiber/matrix or ply properties as input. The properties calculated include laminate strength and stiffness, and electrical and thermal properties as well.

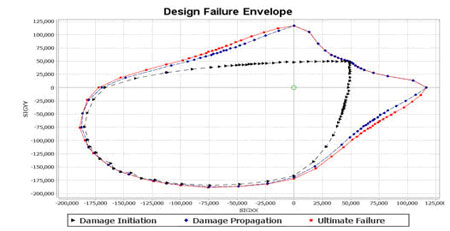

- Design Failure Envelope – Predicts design failure envelope for chosen failure criteria for laminates. Strength, strain, and interactive based failure mechanisms are available (Figure 2). Fiber failure under tension/compression including micro-buckling, matrix cracking under tension and compression and delamination (in-plane and out-of-plane) are determined for the ply and the laminate. Several Failure Criteria can be compared for better understanding and comparison against test data.

- Ply Characterization – Graphically shows variation in strength as a function of ply orientation and fiber or void volume ratio.

- A- & B- Basis Allowables – Predicts equivalent ply properties (mechanical/thermal/electrical) using fiber matrix properties as input. Example of mechanical properties (Figure 1) is ply strength in 11, 22, 33, 12, 23, and 13 directions. Example of electrical properties is ply and laminate conductivity.

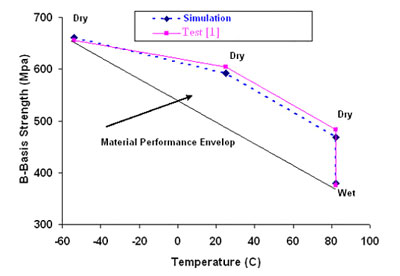

- Ply Level Analysis – Rapid and accurate prediction of A- and B-basis strength allowables for un-notched uniformly stressed coupons. This module provides the option of predicting allowables from a minimal number of test replicates. With a dedicated sensitivity analysis one can determine the influence of manufacturing parameters and material properties on the laminate strength. This helps reduce the scatter and improve the performance of the material (Figure 3 & 4).

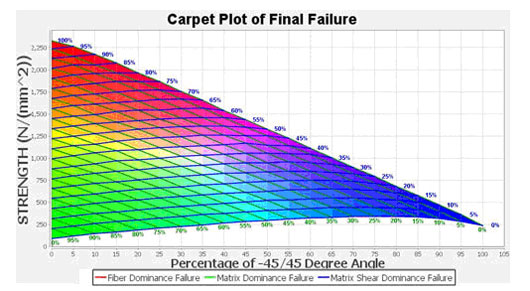

- Parametric Carpet Plots – Carpet plots identify laminate percentages (regions) that are governed by fiber failure dominance, by matrix cracking (transverse and shear) dominance and by combined fiber/matrix failure. The applications and benefits include reducing the number of laminate coupon tests required to verify the entire range of 0°, +/-45° and 90° percentages.

Benefits Provided

- Facilitates material selection and material qualification

- Provides alternate laminate designs

- Generate composite input for commercial FEA solvers (NASTRAN, ABAQUS, ANSYS and others)

- Determine strength allowables with reduced testing

- Assess effect of manufacturing defects and environment on material response

- Reduced testing

- Accelerate certification

Past Experience

Capability was used in qualifying several classes of carbon and glass composites for aerospace and automotive applications.

MCQ Generated Ply Properties

Design Failure Envelope Progression for a [0,90,45,-45] Symmetric Layup

Material Performance Envelope Generated by the Software

Reference

DOT/FAA/AR-03/19, Final Report, “Material Qualification and Equivalency for Polymer Matrix Composite Material System: Updated Procedure” Office of Aviation Research, Washington, D.C. 20591, U.S. Department of Transportation Federal Aviation Administration, September, 2003.

Carpet Plot of Laminate Strength as Function of 0, 45, and 90 degrees Ply Angles (Red = Fiber Failure, Green = Matrix Failure, Blue = Matrix Shear Failure)

A- & B-Basis Allowables -MCQ

Generation of Composite Strength Allowables

A- and B-basis allowable strength values are essential for reducing risk in aircraft structural components made from fiber reinforced polymer composite materials. Risk reduction is achieved by lowering the probability of failure of critical aircraft structures through the use of A- and B-basis design values. For A-basis, at least 99% of the population of material strength values is expected to equal or exceed this tolerance bound with 95% confidence. A-basis strength is applied to single members within an assembly whose failure would result in loss of structural integrity. For B-basis, 90% of the population of material strength values is expected to equal or exceed that strength value with 95% confidence. B-basis strength is applied to redundant structures where failure would result in safe load redistribution. Current practices for determining allowables follow procedures recommended by FAA and working draft of the composite materials handbook CMH-17 Rev G (formerly military handbook Mil-HDBK-17-1F). Determining allowables solely by means of testing [1] is costly and time consuming as large number of composite coupons must be tested under various environments: cold, ambient and elevated temperatures (with and without moisture). AlphaSTAR devised technical approach for calculating allowables with reduced testing. The methodology eliminates unnecessary conservatisms that can contribute to increased weight.

Reference

DOT/FAA/AR-03/19, Final Report, “Material Qualification and Equivalency for Polymer Matrix Composite Material System: Updated Procedure” Office of Aviation Research, Washington, D.C. 20591, U.S. Department of Transportation Federal Aviation Administration, September, 2003.

Objective

Provide material and structural engineers with verified capability for rapid and accurate assessment of laminate response under in-service loading.

Approach

Use lamina level testing per CMH-17 guidelines to reverse engineer sources of uncertainties that produce scatter in material response. The variability is generally caused by: (1) scatter in constituent mechanical properties; (2) variability in composite manufacturing parameters; and (3) manufacturing defects such as void, waviness, and gaps. Then use advanced multi-scale multi-physics progressive failure analysis (MS-PFA) coupled with probabilistic analysis and Bayesian statics update to produce scatter at the laminate level. Lamina level scatter can be used to generate laminate level scatter as indicated in [1]. Data from testing of fewer replicates of composite laminates can be used to guide the determination of allowables. AlpahSTAR developed MCQ (Material Characterization and Qualification) software to determine allowables with reduced testing.

Reference

J. Tomblin, and W. Seneviartne, “Laminate Statistical Allowable Generation for Fiber-Reinforced Composite Materials: Lamina Variability Method”. Report number DOT/FAA/AR-06/53, January 2009. US Department of Transportation, Federal Aviation Administration (Office of Aviation Research and Development), Washington, DC.

Tools Used

MCQ is used to determine allowables for laminate level un-notched coupons following ASTM standards. MCQ is a mesh-less unit cell concept that does not use FEA as long as the state of stress is uniform in the coupon. For all other ASTM coupons (open hole, filed hole, etc.) or general structural component design allowables are determined using MS-PFA invoking finite element solution with progressive failure analysis.

Benefits Provided

- Reduce laminate level testing for the first level of FAA’s building block where testing of a large number of coupons becomes inevitable; test reduction can be on the order of a minimum of 50% as compared to current standards.

- Determine A-basis from B-basis.

- Identify root cause for scatter in material strength.

- Provide guidelines for improving material behavior.

- Applicable to determination of B-basis at any level of FAA’s building block (coupon, element, subcomponent, etc.)

Past Experience

Technology was applied successfully to carbon and glass composites (tape and fabric). The approach consistently provided accurate allowable values. Additionally, AlphaSTAR published extensively on the topic with Joint Publications with key Aerospace Industries and University Partners:

Reference

[2] G. Abumeri, M. Garg, F. Abdi, A. McCloskey and R. Bohner, “Validation of a Computational Approach for Composite Material Allowables Using Sealed Envelope Predictions for Reduced Testing,” SAMPE Journal, September/October 2009.

Advanced Materials -MCQ

Conventional fiber reinforced composite materials exhibit higher specific stiffness and strength than ones exhibited by traditional metal materials. Applications of composite materials lead to weight reduction and energy savings. The matrix system usually a polymeric, ceramic, or a metallic material. The properties are tailorable in plane; however, further enhancement is possible by creating a sandwich material system like fiber metal laminates, honeycomb and foam core, and even by reinforcing the matrix material using nano-materials (e.g., nanotubes, nano-fibers, silica particles, etc.,) and chopped fibers. Engineers also may use 3-dimensional stitched, braided or fabric materials. Performing durability and damage tolerance analysis on structural components made of such advanced composites material systems is a difficult task as range of stiffness, Poisson’s ratio and strength properties are desired for such analysis. The challenge comes from difficulty in performing reliable mechanical tests on nano-materials in a less expensive way.

Objective

It is highly desirable to be able to simulate structural components made of these advanced materials subjected to static, fatigue or impact loading conditions. It is also desirable that the simulation be done without any extensive finite element modeling or several expensive coupons level test data. Recall that usual finite element approach requires extensive modeling efforts whereby the engineer models all the constituents without knowledge of complete set of mechanical material properties, or homogenized model ignoring any possible fiber matrix level root cause issues.

Approach

Since in advance complex material systems the root cause for damage initiation is the constituents, it is vital that constituent level damage evolution be accounted accurately during the load increment without extensive modeling efforts. We recommend the following approach for simulating such problems:

- Characterize the in-situ linear/nonlinear constituent material properties obtained using simple flat coupon test data

- Perform D&DT analysis using less extensive finite element models combined with progressive failure and advanced 3 dimensional micro-mechanics theories at each incremental loading to evaluate the damage progression at the constituent level.

Tools Used

Material characterization is done using the following tools:

- Conventional composites (PMC, CMC, MMC): Material Characterization & Qualification (MCQ)

- Nanocomposites: MCQ Nano

- Metals: Fracture Toughness Determination (FTD) and Fatigue Crack Growth Curve (FCG)

Benefits Provided

- Reduce constituent level testing using expensive scientific tests, for example, Atomic Force Microscope.

- Generate scatter at laminate level by virtually introducing the variation in material properties

- Reverse engineer the constituent properties.

- Provide guidelines for improving material behavior.

- Identify root cause problems for D&DT analysis without extensive FE models

Past Experience

Joint Publications with key Aerospace Industry and University Partners:

Honeycomb Structure

Ceramics

Composite Manufacturing Defects -MCQ

Common composite manufacturing defects include void of different shapes and sizes, different location of void (i.e. within the matrix or in between two adjacent plies). Other forms of manufacturing defects in composite laminates result from hand-Layup and automated fiber placement processes, which can cause intra-ply overlap resulting in fiber waviness and/or resin rich pocket gap defects. The presence of gaps containing resin rich pockets and/or wavy fibers affects the performance of laminate modulus and strength properties. It is important to account for manufacturing defects and their variability on material and structural response.

Challenge

Modeling manufacturing defects by means of finite element analysis (FEA) is impractical. The modeling of voids and fiber waviness is very time consuming. Additionally, use of FEA will introduce other challenges as some voids, when modeled, can cause stress concentration issues. Micro-mechanics based approach is the most efficient approach to model and analyze effects from composite manufacturing defects.

Implications

Not accounting for the deterministic and probabilistic nature of composite manufacturing defects can increase the risk associated with the use of composite sin critical structures such as those used in aerospace. For example, manufacturing defects can reduce the stability of composite structures and reduce their impact resistance. To account for such defects, designers tend to reduce the strength allowables used in design, resulting in increased weight and cost.

How we address it

AlphaSTAR devised a numerical approach combining multi-scale progressive failure analysis to predict the in-situ degraded ply properties containing voids of different sizes and shapes and gaps.

GENOA’s PFA module allows the insertion of manufacturing defects in composite laminates for use in progressive failure analysis.

Benefits Provided

- Simplified practical approach for modeling of manufacturing defects

- Determination of equivalent ply properties with defects for use in multi-scale progressive failure analysis

- Capture damage and fracture evolution in presence of manufacturing defects

- Determine loss in strength and stiffness due to manufacturing defects

- Reduce number of tests by validating coupons tests with defects then use approach to assess effects at component level

Testimonials

AlphaSTAR assessed risks associated with composite manufacturing defects for aerospace and automotive industries.

Reference

J. Sawicki, P. J. Minguet, “The Effect of Interply Overlaps and Gaps upon the Compression Strength of Composite Laminates” 39th AIAA/SDM Conference Paper, AIAA-98-1786, Long Beach, CA, 1998

Damage marked in red in open hole laminate under compression with gap defects obtained from multi-scale PFA