複合材進展性損傷/破壊評価解析ソフトGENOA/MCQ

複合材進展性損傷/破壊評価解析ソフトGENOA/MCQ -製品概要

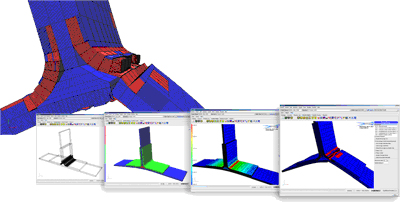

GENOA

GENOAは、材料特性、耐久性&損傷トレランス(Durability&Damage Tolerance:D&DT)、信頼性エンジニアリングの統合ソフトウェアです。

このソフトウェアは、Multi-scale (Micro-macro) Progressive Failure Analysis (PFA)機能により、汎用FEAパッケージの制限を拡大します。

Advanced failure mechanisms(matrix, fiber, lamina, laminate, Honeycomb sandwich)を使うことにより、静的、周期的(低/高サイクル疲労、2段階)、Power Spectrum Density (PSD)と熱荷重により引き起こされた損傷から材料の劣化まで構造応答を研究することが可能です。

さらにGENOAのPFAは、製造欠陥(形状、サイズ)、ファイバー波形、残留応力、湿気および温度の影響を説明します。 材料システムの幅広い領域は、金属、セラミック、複合材とナノ複合材を含めて取り扱うことが可能です。

最近では、Polymer Matrix Composites (PMC) と Ceramic Matrix Composites (CMC)が含まれます。

GENOAは、従来の2Dテープおよび繊維ラミネート・レイアップだけでなく3D波形、braids、短繊維も分析することが可能という点で独特です。

MCQ-Composites

MCQ(Material Characterization and Qualification)は設計ユーザーに、ユーザーフレンドリーなグラフィックユーザーインターフェイス(GUI)により容易に利用可能な、高精度、最先端の複合材解析ツールを提供します。

MCQは、有限要素解析の単純または複雑な構造部品の入力として使用可能な、特性と品質材料プロパティのためにデザインされています。

手法は、広く受け入れられているClassical Laminate Theory (CLT) とMicromechanicsに依るものです。

これは、即座にユーザーが、関心のある材料(複合材、ハイブリッド、金属またはセラミック材料系)のための膨大な量の情報を生成することを可能とします。

複合材進展性損傷/破壊評価解析ソフトGENOA/MCQ -動作環境

- Dual core / Quad Core CPU (64 bit)以上

- 8~12GB RAM以上

- 1~2GB Video RAM以上

- Windows 7 (64 bit), Linux (64 bit)

- Latest Java & Java 3D (Free from Oracle.com)

GENOA製品ハイライト

- 金属、ポリマーとセラミック複合材の等価材料特性:Equivalent Material Properties of Metallic, Polymer and Ceramic Composites

-

- GENOA determines material strength, moduli, moisture, thermal, and heat conductivity properties. Degradation of material properties to environmental (moisture, thermal), and manufacturing (defects, residual strains) is included.

- 耐久性と損傷トレランス:Durability & Damage Tolerance

-

- GENOA evaluates the material/structural response, including: life cycle, degradation of material properties due to initiation, location of failure, and growth of damage under in-service operations and environments (static, dynamic, thermal, creep, impact, and low/high/random frequency cyclic fatigue). GENOA identifies the percent contribution of various possible composite failure modes. GENOA predicts the inspection interval, incipient damage locations, and margin of safety.

- 製造可能性:Manufacturability

-

- GENOA accounts for minimum defect occurrences (i.e. voids (shape, size), buckling, wrinkling), fiber jamming, and fiber volume fraction. It can handle precision manufacturing, smart materials and processes, and smart structures. GENOA can determine the best fit to a shape as well as optimum aeroelastic fiber angle orientations.

- 仮想試験ツール:Virtual Testing Tool

-

- GENOA virtually duplicates the experimental testing process. It can computationally replicate photoelasticity, far field strains, material fracture parameters, strain gage readings, and margin of safety calculations.

- 確率的な破損解析:Probabilistic Failure Analysis

-

- GENOA’s Probabilistic Failure Analysis: Identifies progressive damage parameters and their sensitivity; Evaluates the uncertainty of material strength to material parameters; Determines sensitivities of failure modes to design parameters to facilitate targeting design parameter changes that will be most effective in reducing probability of a given failure mode from occurring, and: calculates the probability of failure.

- GENOAについてさらに知りたい方は、製品オフィシャルサイトをご覧ください。

MCQ製品ハイライト

- Tape/Braid/fabrics (material selection and Analysts)

-

- No detailed FE models required

- May require braid angle information from micro-graphs for the Braid and fabrics

- Laminate A- & B-Basis Allowables (for material certification and qualification)

-

- Potential to save 40 to 60% coupon testing

- May require input from ASTM standard Unidirectional laminate test data (ply properties)

- Reverse Engineer unknown values (ply/fiber/matrix) using in-plane ply properties (FE Analysts)

-

- Predict effective constituent (fiber and matrix) modulus, Poisson’s ratio and strength properties from ply properties

- Additional information such as fiber and void volume ratio is required as input. Also fiber modulus available from vendor is required as input

- Account for material nonlinearity for improved accuracy (FE Analysts)

-

- Predicts effective matrix nonlinearity that results in laminate level nonlinearity from in-plane shear and transverse compression ASTM standard tests

- Requires full stress-strain data from tests for in-plane shear and transverse compression and tension

- Parametric carpet plot (Designers and material selection)

-

- Generates laminate material properties plot as a function of angled ply distribution through-the-thickness

- Requires limited test data for validation for couple of laminates

- Sandwich Material properties (FE Analysts)

-

- Predicts material properties for sandwich materials (foam + composites, honeycomb + composites, composites + metals [GLARE, CentrAl], etc)

- Requires basic ASTM standard coupon testing for individual constituent. Note that composite can be at ply level, metal from MMPDS/Mil-HDBK 5H, foam/Honeycomb from literature/vendor

- Generate input (unknown material properties) for other well known FE solvers (MD NASTRAN, NEi NASTRAN, ABAQUS, LS-DYNA, ANSYS, Fire Hole, ESAComp and others) (FE Analysts and designers)

-

- In-Situ Fiber/matrix properties. Fiber is assumed to be transversely isotropic or isotropic and matrix as isotropic

- Predicts apparent out-of-plane properties for the fiber and ply using only in-plane ply test data

- Need Ply test data as input

- 14 Test Validation Cases

-

- Several different material systems ranging from low modulus low strength matrix and fiber to high modulus and high strength fibers

- Includes test data with documentation and references

- MCQについてさらに知りたい方は、製品オフィシャルサイトをご覧ください。