D&DT Analysis

複合材進展性損傷/破壊評価解析ソフトGENOA/MCQ -機能情報

GENOA-Durability and Damage Tolerance

Background

Durability and damage tolerance (D&DT) of composite structures is a very important element of the overall design process. For airframe structures, durability and damage tolerance provide guideline for setting up an inspection plan for each principal structural element so damage (including micro-cracks) under service loading do not grow to failure prior to detection. It is imperative to assess all stages of damage evolution in composite structures to determine when, where, and why damage and fracture initiate and propagates. AlphaSTAR integrated D&DT methods with damage tracking and fracture and finite element analysis to evaluate damage growth in composite structures. It allows the analyst to include in the D&DT analysis manufacturing defects depicting “as-is” state of the structure.

Objective

Provide stress engineers with robust methodology for determining all stages of damage evolution in composite structures and answer critical design questions on why, where, and when damage and fracture initiates and what can be done to fix it.

Approach

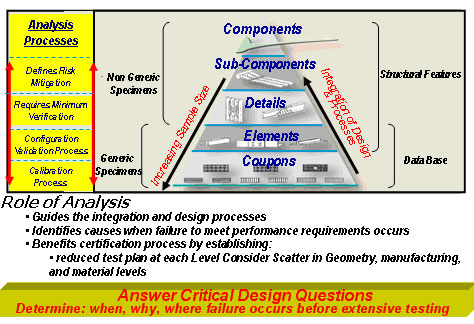

Use GENOA’s multi-scale progressive failure analysis MS-PFA to determine all stages of damage evolution under service loading. Physics based composite damage and failure mechanisms are used by MS-PFA to interrogate the structural response. Matrix cracking under tension, compression, shear, and fiber failure under tension and compression (including crushing, fiber-matrix debonding, and fiber micro-buckling) are evaluated. Analyst has a choice of using fiber/matrix or ply properties as input to the analysis. Commercial FEA stress solvers such as (NASTRAN, ABAQUS, ANSYS, and others) are augmented for damage tracking and fracture with GENOA’s MS-PFA.

D&DT is evaluated under all types of loading including static, dynamic (low/high velocity impact), low/high cycle fatigue, and creep loading.

Tools Used

Relevant GENOA modules are MS-PFA: static, fatigue (low cycle/harmonic/ random/power spectrum density, single and multi-stage), and impact (explicit low and high velocity).

Benefits Provided

- Determine damage history/locations/modes under service loading.

- Determine ultimate (failure) load

- Evaluate and manage risk associated resulting from scatter and manufacturing defects (effect of void variability on compression strength, shape of void, location of void, etc.)

- Test guidance by obtaining a priori prediction to determine where to place instrumentation

- Identify test anomalies

- Aid in re-design of structural component

- Develop an inspection plan

- Support certification plans

- Supports test reduction goals

Past Experience

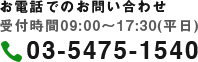

D&DT of composite aircraft and automotive structures and bridges. Examples include low and high velocity impact of aerospace and automotive structures, progressive failure analysis of stiffened wing and fuselage panels, and wing structures. Technology was validated for every step of the FAA building block approach (from coupon level to sub-element, element, and structural components),

D&DT Approach is Applicable to all Levels of FAA Building Block

D&DT of A Stiffened Wing Panel With Discrete Source Damage Under Tension

Ref: F. Rognin, H. Zhang and F. Abdi, K. Nikbin, “Robust Design of Composite Stiffened Panels under Discrete Source Damage, a Combined Durability-Reliability Evaluation”, 51th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Orlando, Florida, 12-15 April 2010.