Robust Design

複合材進展性損傷/破壊評価解析ソフトGENOA/MCQ -機能情報

GENOA-Robust Design

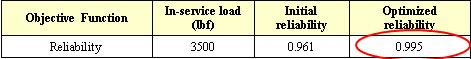

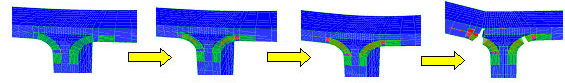

Robust design is a process that ensures that a given design is characterized with maximum reliability, maximum durability, and minimum weight. The approach ensures that the performance of the considered structural component is insensitive to small scatter or variations in material properties, manufacturing, loads, and geometry. With the use of composites, robust design is used to prevent initial micro-racking and initial delamination from growing to pose a threat to the integrity of the structure.

Damage Evolution as Load Increases – Naval Joint Load Displacement (Analysis and Test)

Objective

Provide design engineers with robust methodology for sizing structural components to meet requirements for reliability, durability, and weight.

Approach

Use GENOA’s multi-scale progressive failure analysis MS-PFA robust design module considering uncertainties in material properties, manufacturing, geometry, shape, and loads. Manufacturing variables include composite layup and ply thickness. The capability delivers optimized manufacturing variables for maximum reliability, maximum durability, and minimum reliability. Sensitivity analysis is used to identify critical design variables that influence the reliability, durability, and weight.

Robust design is done using any in-service loading including static and fatigue.

Tools Used

Relevant GENOA modules are MS-PFA Robust Design and Probabilistic Analysis Modules.

Benefits Provided

- Quantification of reliability for a given design

- Provide alternate designs for weight management

- Identify and control influential sources of scatter to minimize variability in the design

- Support test reduction goals

- Shorten iterative design cycles

- Reduce risk by maximizing reliability and durability

- Robust design of aircraft panels and automotive suspension systems.